In the years ahead, food brands will be judged less by what they claim and more by what they can visibly demonstrate. By 2026, trust will be a defining differentiator — and that trust is often formed before a consumer ever tastes the product. More often than not, it begins with the package itself.

Across the food industry, packaging is taking on a more strategic role. Once treated as a functional necessity, it is now recognized as a decision that directly affects food safety, shelf life, labor demands, regulatory readiness, and brand credibility. From Inline Plastics’ vantage point as a long-time packaging manufacturer, these shifts are becoming clearer as customer priorities evolve.

Changing consumer behavior is a major driver behind this evolution. More Americans now rely on grocery prepared foods, deli offerings, and grab-and-go meals as substitutes for traditional dining. These purchases are no longer occasional conveniences; they are full meals meant to be transported, stored, and eaten later. As a result, packaging must perform across a wider range of conditions, often with little tolerance for failure.

Food safety expectations have also changed. Shoppers are more aware of how food is handled and more skeptical of products that appear unsecured. A container that looks compromised can undermine confidence immediately, regardless of the brand behind it. Visible tamper protection has become a baseline expectation, signaling that food has been protected from preparation through purchase.

In grab-and-go environments, packaging has only seconds to communicate freshness, safety, and value. Poor clarity, questionable seals, or weak construction can cause shoppers to pass a product by. The absence of visible protection introduces real business risk. Without tamper resistance, operators face greater exposure to customer distrust, waste, and regulatory scrutiny. When complaints or investigations arise, packaging often becomes part of the evaluation. Containers that provide clear evidence of integrity help reduce uncertainty and protect brands from costly downstream consequences.

For operators, those moments translate into lost sales, increased shrink, and prepared food that never leaves the shelf. Containers that visibly protect food help prevent those outcomes while reinforcing consumer confidence.

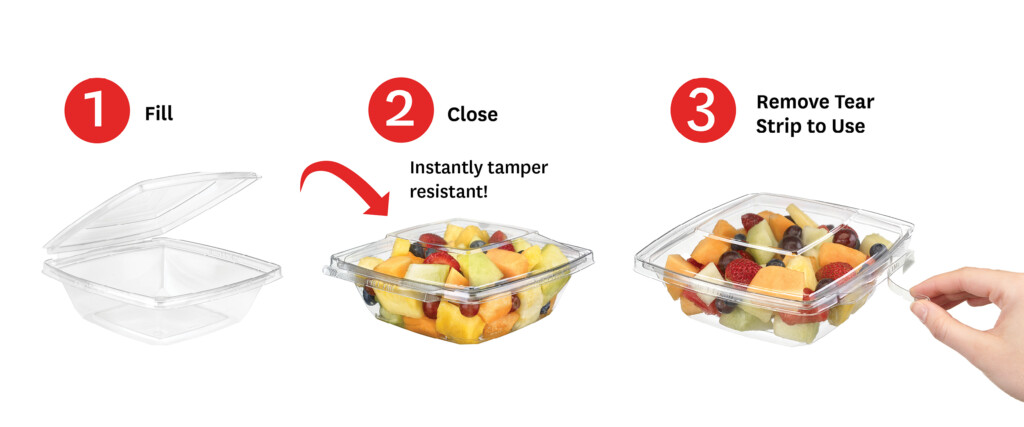

Tamper-evident and tamper-resistant solutions, such as Inline Plastics’ Safe-T-Fresh® line, made from PET, address this challenge by combining visible proof of integrity with built-in protection. A tamper-evident tear strip provides a clear visual cue if a package has been opened, while the tamper-resistant seal helps prevent unnoticed access before purchase. Together, these features make protection easy to recognize at the shelf, reducing hesitation and lowering the risk of complaints, food safety concerns, or product removals in high-traffic retail environments.

As grab-and-go expands beyond cold foods, packaging must also support hot and heat-and-eat applications without adding risk or labor. Inline Plastics’ Safe-T-Chef® line, made from polypropylene, is designed for these conditions, combining heat tolerance with tamper protection to support hot fill, transport, and reheating. The containers maintain strength and clarity through temperature changes, allowing operators to offer take-home meals and ready-to-reheat options without adding operational complexity or compromising food safety.

Presentation has become even more important as portion sizes shrink and purchasing becomes more intentional. While consumers remain value-conscious, indulgent items such as desserts, sides, and premium prepared foods continue to play a role in grab-and-go assortments. These products rely heavily on appearance to justify their price, particularly in refrigerated cases where decisions are made quickly.

Smaller portions leave little room for visual compromise. Cloudy materials, scratches, or containers that flex or warp can erode perceived value instantly. Clear, rigid packaging that maintains its shape and showcases the food inside helps reinforce quality and supports premium pricing, protecting margin as well as product.

Sustainability expectations continue to rise alongside these performance demands. Claims alone are no longer enough; consumers and retailers increasingly look for measurable progress. Packaging is scrutinized not only for performance, but for how responsibly materials are sourced and used.

For many food brands, this means finding solutions that support circularity without sacrificing food safety or shelf life. Inline Plastics incorporates 10% post-consumer recycled content into all PET products, verified by a third-party, allowing brands to advance sustainability goals while maintaining clarity, strength, and food-safe performance. The challenge today is no longer choosing between sustainability and functionality, but identifying solutions that consistently deliver both.

Taken together, these trends point to a clear reality: packaging now sits at the intersection of safety, efficiency, sustainability, and trust. Decisions made at the container level influence shrink, labor demands, compliance readiness, and brand consistency across locations. Brands that succeed in the years ahead will treat packaging as a strategic asset — choosing solutions that protect food, reinforce trust, and support the business long after the sale is made.

Let Inline Plastics help identify packaging that fits your operation. Talk to them today!