Ramping Up Production via Continuous Systems

Food processors around the world are increasing production volumes and efficiencies by incorporating more advanced, continuous cooking and chilling systems.

As food processors around the world increase production and gain access to international markets, they are shifting from conventional batch processing to more advanced and efficient continuous cooking, chilling and freezing systems.

As food processors around the world increase production and gain access to international markets, they are shifting from conventional batch processing to more advanced and efficient continuous cooking, chilling and freezing systems.

To remain competitive and also meet consumers’ broadening preferences, large and small processors are adopting continuous systems of various capacities that can provide higher productivity and dramatically increased yields as well as improved food safety and quality.

A wide range of continuous cooking equipment is getting attention, like sous-vide cookers, small footprint “spiral” ovens, continuous grilling systems for searing and barmarking – anything that can further automate this “value-added” market. Each of these eliminates inefficiencies of batch cooking, including manual loading, inconsistent results, double handling, and extended cooking times.

In South Africa one of the leading domestic processors, Paarman Foods, has incorporated a highly efficient spiral oven into its production facility to facilitate the company’s rapid growth.

Paarman, an acclaimed family-owned food processor based in Cape Town, produces a wide selection spices, sauces, seasonings, mixes and dressings as well as protein products for retailers. The company also manufactures for a select number of private label companies as well as servicing a large domestic food services.

Paarman, an acclaimed family-owned food processor based in Cape Town, produces a wide selection spices, sauces, seasonings, mixes and dressings as well as protein products for retailers. The company also manufactures for a select number of private label companies as well as servicing a large domestic food services.

Paarman Foods was founded in the 1980s by Ina Paarman, who was inspired by her Grandma’s homemade recipes when she was a child. She worked in London and travelled extensively, soaking up everything she could about the cuisines of other cultures. She combined elements of many of these cuisines with the uniquely South African style and, after a successful teaching and lecturing career, started Ina’s Kitchen, creating various mixes of spices and seasonings in a converted garage at her home in Cape Town.

In the 1990s, Ina’s son Graham expanded the food processing facility and product line to the point where it has become a significant business servicing both local and international markets with a diverse product offering.

Many Paarman items were already exported to retailers around the world to make them available for South Africans living abroad who were longing for an authentic taste from home. (Many processors from different regions and cultures can appreciate this opportunity.)

Many Paarman items were already exported to retailers around the world to make them available for South Africans living abroad who were longing for an authentic taste from home. (Many processors from different regions and cultures can appreciate this opportunity.)

As Paarman Foods continued to grow, it was confronted with the need to ramp up production. Yet, management was insistent on incorporating manufacturing processes and equipment that would enable the company to continue with its passion – producing authentic home-style foods –but now in increased volumes.

“We continuously revisit our recipe formulations and production methods in a quest to make ‘homemade food’ on a factory scale,” says Nikki Edwards, manager of product development. “Our philosophy is to base our recipes on classic ingredients and preparation methods to develop a product that is instantly ready-to-eat yet delivers the same experience as if the customer had made it themselves from scratch.”

Recently, Paarman decided to acquire more advanced equipment to cook a number of spiced protein products (lamb, chicken and beef) as well as vegetables that are used in various products. The equipment upgrade would provide greater throughput while preserving the traditional authenticity of these foods.

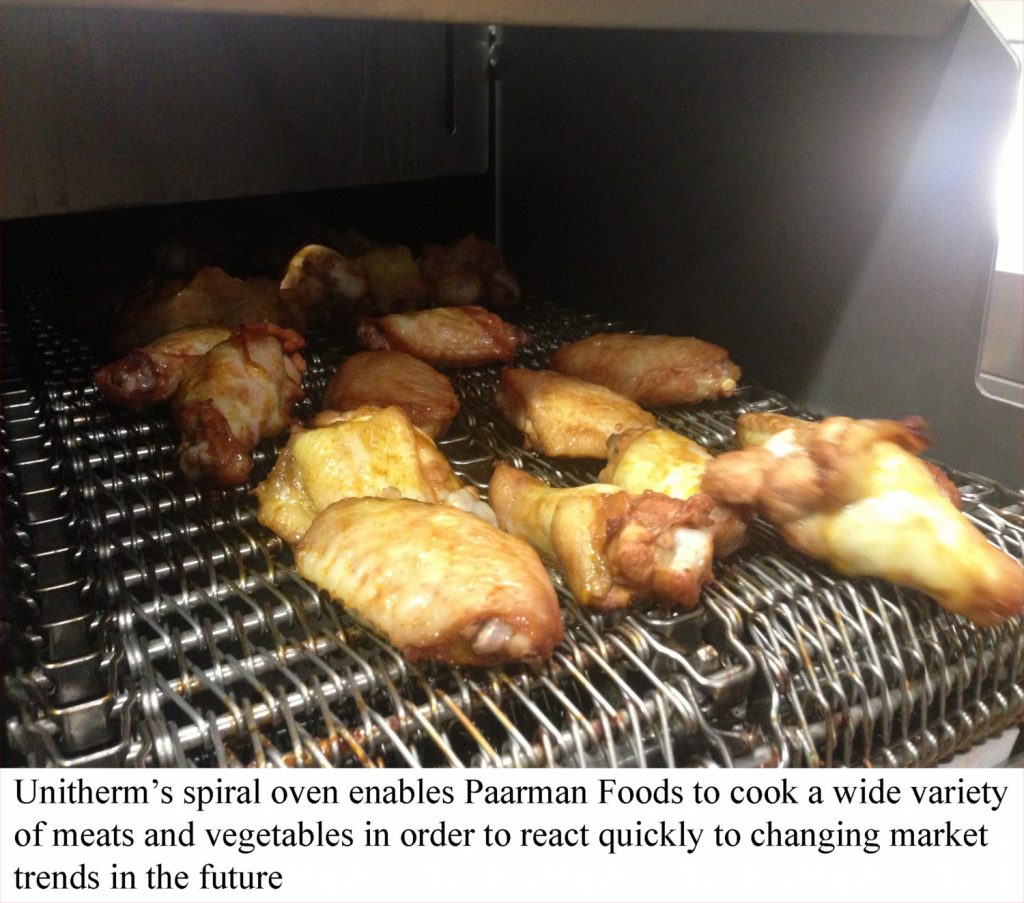

In 2015 the company acquired a Micro Spiral Oven™ to cook vegetable and protein products such as seasoned lamb, beef and chicken dishes.

Developed and manufactured by Unitherm Food Systems (unithermfoodsystems.com), this spiral oven provides a number of benefits over linear ovens. The “micro” oven is a small, compact version of a variety of sizes available from Unitherm. The benefit that most appealed to Paarman Foods was the ability to maintain home-style food qualities.

Micro Spiral Ovens are sized as entry-level systems that are remarkably productive and versatile. They have the flexibility of a batch system, but the efficiencies and yield advantages of a continuous system. These Micro Spiral Ovens can roast, steam, bake, or combination cook.

“The flexibility of Unitherm’s spiral oven enables us to cook a wide variety of meats and vegetables in order to react quickly to changing market trends in the future,” Edwards says. The on-board controls enable us to utilize many different recipes and also scale up on product throughput as required to meet increasing demands. At the same time, the automation features of the equipment also allow us to enhance productivity through labor savings.”

While Paarman Foods may be a leader in the region, many other local processors are taking note and looking to modernize their cooking processes to better compete, grow and export their traditional South African fare throughout the world.

For information contact: Unitherm Food Systems, 502 Industrial Road, Bristow, OK 74010; Phone: 918-367-0197; Fax: 918-367-5440; email: unitherm@unithermfoodsystems.com; or visit the web site www.unithermfoodsystems.com