by Rich Clifton, Portfolio Manager – Beverage & Robotics at R.A Jones

With the exponential growth of the beverage industry in recent years, there are numerous methods brand manufacturers can implement to match increasing consumer demand. The outbreak of the COVID-19 pandemic severely disrupted the beverage industry, leading to a notable rise in in-home consumption vs. serving consumers out-of-the home.

Packaging Innovations: Quenching Consumer Thirst for Speed

Now, reaching the endemic stage of the pandemic, these dynamics have shifted again, reaching higher consumption levels than recorded pre-pandemic. In fact, according to Statista, revenue in the US beverage market is projected to reach $89.53 billion USD this year and continue growing with an annual growth rate of 16% until 2027. This compels brand manufacturers to integrate automation practices into their operations to ensure greater speeds and efficiency to meet growing consumer demand.

As a global leader in the design and manufacturing of beverage packaging machines, R.A Jones has been supplying multipacker machines to many of the major beverage brands, co-packers and distributors for decades. With beverage companies offering a greater variety of drink options today, R.A Jones was challenged with developing new technological advancements in packaging machinery that could increase the speed in which manufacturers could produce different multipack can sizes.

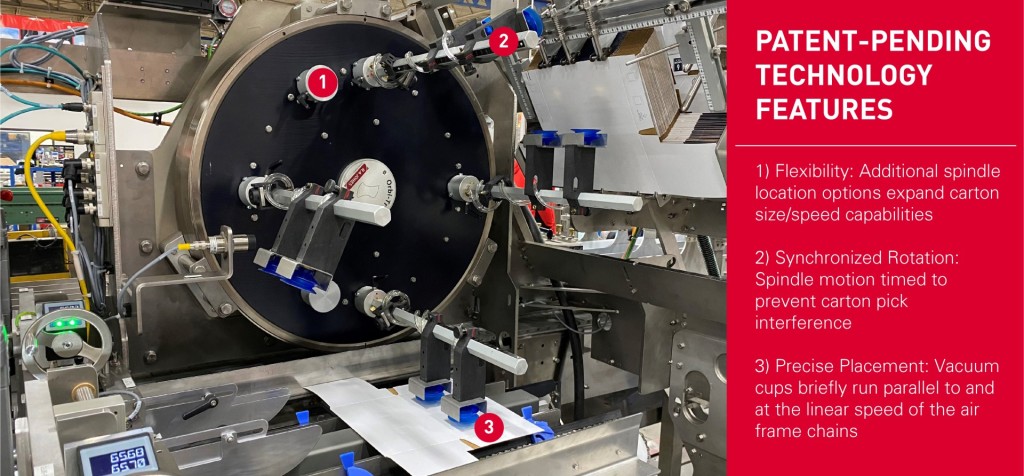

R.A Jones responded with the launch of Orbi-Trak TC-6, an innovative carton feed technology which could be easily integrated into its popular Meridian XR MPS-300 machines, enabling beverage and food manufacturers to run a variety of canned product configurations at an unprecedented speed of 345 cartons per minute. This new speed up kit surpasses the current standard speed of 300 cartons a minute, making R.A Jones’ multipacker machines the fastest in the industry.

Orbi-Trak TC6 is outfitted with six possible spindle carton pick and place locations rather than four. With two additional spindle locations, R.A Jones has expanded the number of spindles used which increases the speed capabilities of the machine, boosting overall production rates. The speed up kit can be added to Meridian XR machines already in service or new machines to sustain speeds of 345 cartons per minute for 4, 6 and 8 pack configurations, while also improving carton handling for larger configurations.

Innovation that Excites

The new carton feed system design did not come without trial and error; experience has shown that increasing carton speeds can lead to carton handling issues and lowered efficiency rates, which result in production line downtime. However, with the company’s long history and expertise in developing advanced packaging solutions that disrupt markets and drive consumer trends, R.A Jones was able to re-engineer the spindle rotation so it was synchronized and would not interfere with the carton being picked up. By slowing down the spindle speed, the carton can better align with the speed of the air frame chains, allowing for a smoother hand off between the two devices. The matching speed is essential in preventing improperly formed cartons jams while still providing customers with improved reliability and increased efficiency.

Beverage Trends Drive Innovation

However, beyond the overall growing market, there are a few consumer beverage trends brand manufacturers should be aware of. For example, research demonstrates that following the heels of the pandemic, consumers have started to move away from sugary drinks and turn more to functional and health-focused beverages.

To address these trends, a CPG can substantially increase flexibility within their production line by implementing equipment that expands its capacity to change can diameters. Brand manufacturers that can accommodate various beverage can sizes, such as the standard and sleeker specialty cans, within the same machine can increase production capacity and maintain greater efficiency rates.

R.A Jones was able to accomplish this by upgrading its mid-range packaging machine to allow for greater flexibility for single-tier can multi-packing. As a result, manufacturers can now run greater can and carton size ranges from 4-and 6-packs of standard and sleek cans, all the way up to 24-packs at speeds of 210 packs per minute on the new compact Meridian MPSC-210.

Read Also: Luxury High Tea Goes Green with Compostables – F & B

With no signs that the beverage market is going to let up, brands must look to partner with OEMs that are going to help them meet consumer needs and stay ahead of the curve.

To learn more about R.A Jones’ multipacker machines and the new speed up kit, visit www.rajones.com.